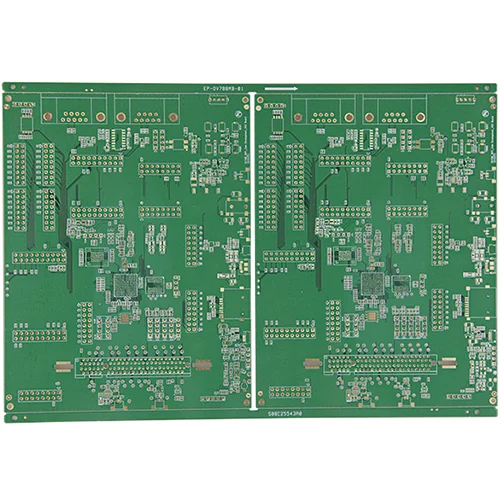

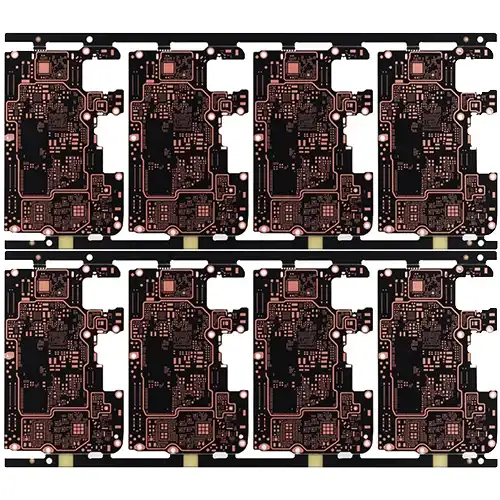

Name: Car driving recorder HDI PCB

Tier: 1+6+1

Sheet: EM825

Plate thickness: 1.6mm

Size: 242mm*165mm

Minimum blind hole: 0.1mm

Min Buried Via: 0.25mm

Minimum line width: 0.088mm

Minimum line spacing: 0.087mm

Surface Treatment: Immersion Gold

Outline tolerance: +/-0.1mm

Special requirements: L3-L6 resin plug holes

10-layer 1-stage HDI communication PCB

Name: 10-layer 1-stage HDI communication PCB

Layers: 1+8+1

Sheet: FR4 Tg170

Plate thickness: 1.2mm

Panel size: 110.8*94.8mm/4

Outer copper thickness: 35μm

Inner layer copper thickness: 18μm

Minimum through hole: 0.20mm

Minimum blind hole: 0.10mm

Minimum BGA: 0.20mm

Line width and line spacing: 2.5/2.2mil

Surface Treatment: Immersion Gold 2μ”+OSP

Application field: communication

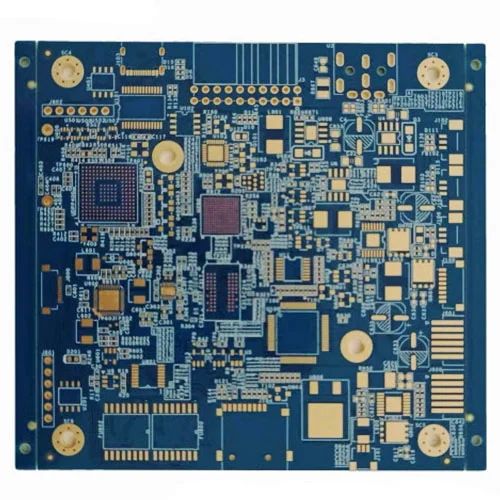

6L 2+N+2 HDI Communication PCB

Name: 6L 2+N+2 HDI Communication PCB

Model: 2+N+2 HDI communication PCB

Layers: 6Layers

Material: IT150

Construction : 2+2+2 HDI PCB

Finished Thickness: 0.8mm

Copper Thickness: 0.5OZ

Color: Green/White

Surface Treatment: Immersion Gold+OSP

Min Trace / Space: 3mil/3mil

Min Hole: Laser Hole 0.1mm

Application: Communication HDI PCB

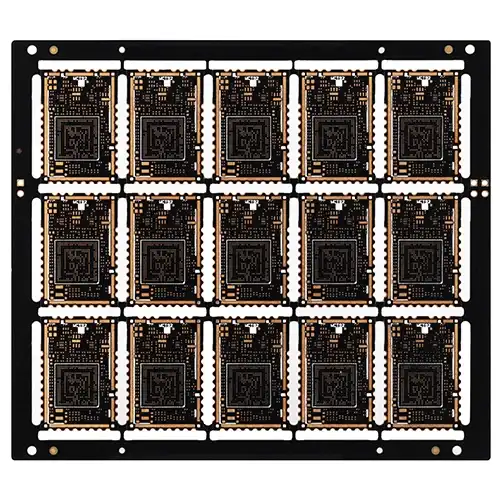

Name: 6L 2+N+2 HDI WiFi Module PCB

Layers: 6Layers

Material: FR4 Tg170

Construction : 2+2+2 HDI PCB

Finished Thickness: 0.8mm

Copper Thickness: 1OZ

Color: Black/White

Surface Treatment: Immersion Gold+OSP

Min Trace / Space: 3mil/3mil

Min Hole: Laser Hole 0.1mm

Application: WiFi module PCB

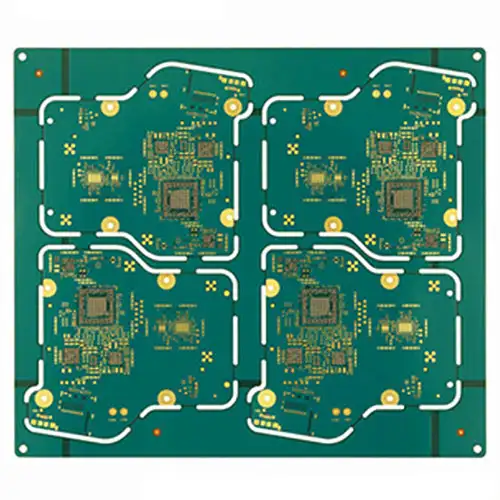

Name: 6-layer 1-stage HDI PCB

Layers: 1+4+1

Sheet: FR4 Tg150

Plate thickness: 1.6mm

Panel size 105*95mm/1

Outer copper thickness: 35μm

Inner layer copper thickness: 30μm

Minimum through hole: 0.20mm

Minimum blind hole: 0.10mm

Minimum BGA: 0.20mm

Line width line spacing: 3/3mil

Surface Treatment: Immersion Gold 2μ”+OSP

Application field: industrial control

Name: 10-layer 3-stage HDI PCB

Layers: 3+4+3

Sheet: FR4 Tg170

Plate thickness: 1.2mm

Panel size: 126*118mm/4

Outer copper thickness: 35μm

Inner layer copper thickness: 18μm

Minimum through hole: 0.20mm

Minimum blind hole: 0.10mm

Minimum BGA: 0.25mm

Line width and spacing: 2.8/3.2mil

Surface Treatment: Immersion Gold 2μ”+OSP

- HDI PCB Capability

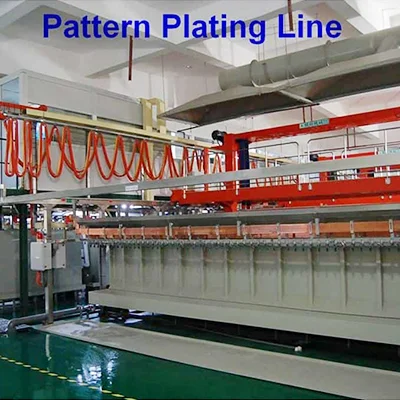

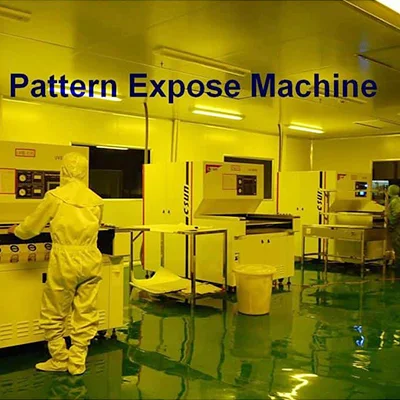

- PCB manufacturing equipment

Introducing our high-density interconnect printed circuit boards (HDI PCB), the epitome of cutting-edge technology in the world of electronics. Designed to meet the demands of modern electronic devices, our HDI PCBs offer superior performance, reliability, and miniaturization capabilities.

Our HDI PCBs are meticulously engineered using advanced manufacturing processes and materials, resulting in a compact design with highly efficient interconnections.

These PCBs boast a high circuit density, enabling the integration of numerous components within a smaller footprint. Whether you are working on smartphones, tablets, wearable devices, or any other compact electronic device, our HDI PCBs provide the ideal solution.

Advantages of HDI PCB:

- Enhanced Miniaturization: HDI PCBs are renowned for their ability to pack more circuitry into smaller form factors. By utilizing advanced microvia and fine-pitch technologies, HDI PCBs significantly reduce the overall size and weight of electronic devices, allowing for sleek and compact designs.

- Increased Signal Integrity: With HDI PCBs, signal integrity is greatly improved. The shorter trace lengths and reduced electromagnetic interference (EMI) result in minimal signal loss and noise, ensuring reliable and high-quality performance of the electronic device.

- Improved Electrical Performance: HDI PCBs offer excellent electrical performance due to their optimized routing and minimized parasitic capacitance and inductance. This leads to faster signal propagation and reduced power consumption, resulting in enhanced overall device efficiency.

- Enhanced Reliability: The advanced manufacturing techniques used in HDI PCBs ensure a high level of reliability and durability. These PCBs are resistant to thermal stress, vibration, and mechanical strain. It also makes them ideal for applications that require long-term reliability, such as automotive electronics and medical devices.

- Design Flexibility: HDI PCBs provide greater design flexibility, allowing for more complex and advanced circuitry designs. This flexibility enables the integration of multiple functionalities within a single board. It also reduces the need for additional PCBs and enhancing overall system performance.

| HDI (High Density Interconnect) PCB Process Capability | ||

| Item | batch | Template |

| layers | 4-16 Layers | 4-24 Layers |

| Plate thickness range | 0.6-3.2mm | 0.4-6.0mm |

| highest order | 4+N+4 | Any layer innterconnected |

| Minimum laser hole | 4mil (0.1mm) | 3mil (0.075mm) |

| Laser process | CO2 Laser Machine | CO2 Laser Machine |

| Tg value | 140/150/170°C | 140/150/170°C |

| hole copper | 12-18μm | 12-18μm |

| Impedance tolerance | +/-10% | +/-7% |

| interlayer alignment | +/-3mil | +/-2mil |

| Solder Mask Alignment | +/-2mil | +/-1mil |

| Minimum line width/line spacing | 2.5/2.5mil | 2.0/2.0mil |

| Smallest grommet | 2.5mil | 2.5mil |

| Minimum through hole | 8mil (0.2mm) | 6mil(0.15mm) |

| smallest micropore | 4.0mil | 3.0mil |

| Minimum media thickness | 3.0mil | 2.0mil |

| Minimum pad | 12mil | 10mil |

| Micropore Aperture Aspect Ratio | 1:1 | 1:2:1 |

PCB Drilling machine

PCB pattern plating line

PCB solder mask expose machine

PCB pattern expose machine

Strip film etching line

Solder mask screen silk print machine

Solder mask scrubbing line

PCB Flying Probe Test (FPT)

Fully automatic exposure machine