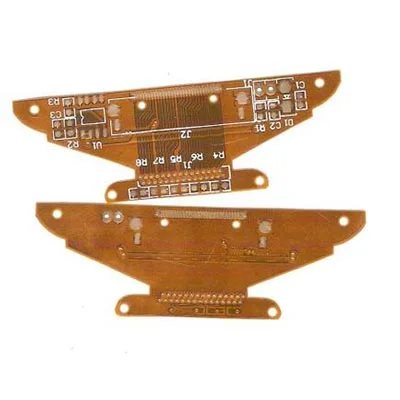

Automotive Dashboard Flexible Circuit Board

Name: Car dashboard soft board

Layers: 2 layers

Plate Thickness: 0.12mm

Material: double-sided non-adhesive electrolytic material

Copper Thickness: 1/2 OZ

Finish: Immersion Gold 1 microinch

Minimum line width/line spacing: 0.08mm/0.075mm

FR4 reinforcement thickness: 0.2mm

Four-layer impedance fpc circuit board

Name: Four-layer impedance fpc circuit board

Application: Machine Equipment

Type: Four-layer FPC circuit board

Minimum drilling: 0.2mm

Minimum line width/line spacing: 0.1mm/0.1mm

Finished thickness: 0.25+/-0.05mm

Reinforcement: L40.25mmFR4 reinforcement

Five-layer vehicle fpc circuit board

Five-layer vehicle fpc circuit board

Application: machine equipment

Type: Four-layer FPC soft board

Minimum drilling: 0.2mm

Minimum line width/line spacing: 0.1mm/0.1mm

Finished thickness: 0.3+/-0.05mm

Reinforcement: 0.4mmFR4 reinforcement on the front and back

Process requirements: differential impedance of 90 ohms +/- 10% ohms

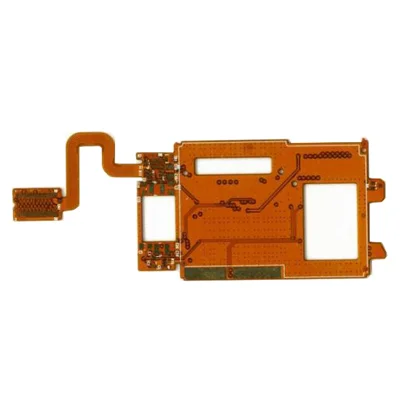

Double-sided smart wearable fpc circuit board

Name: Double-sided smart wearable fpc circuit board

Basic Parameters: Application: Smart Watch

Type: Double-sided FPC circuit board

Line width/line spacing: 0.73mm/0.54mm

Tolerance: +/-0.03mm

Thickness: 0.13mm

Surface treatment: Immersion gold 1u

Six-layer Flexible Circuit Board

Name: Six-layer PC impedance board

Application: Machine Equipment

Type: Six-layer FPC circuit board

Minimum drilling: 0.2mm

Minimum line width/line spacing: 0.1mm/0.1mm

Finished thickness: 0.25+/-0.03mm

Reinforcement: 0.25mm steel sheet reinforcement on both sides

Surface treatment: Immersion gold (sand blasting, nickel thickness 120 miles; gold thickness 2 miles)

Double-sided FPC flexible circuit board

Name: Double-sided FPC Flexible circuit board

Basic Parameters: Application: Medical Equipment

Type: Double-sided FPC soft board

Size: 70.5*117.2mm

Minimum drilling: 0.15mm

Plate thickness: 0.1mm

Reinforcement: 0.5mm FR4 reinforcement on the back of the pad

Surface treatment: Shen Jin 1 mile

- FPC Fabrication Capability

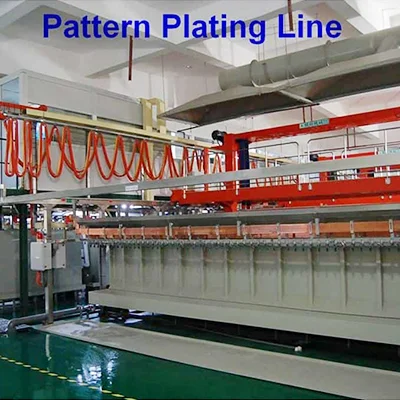

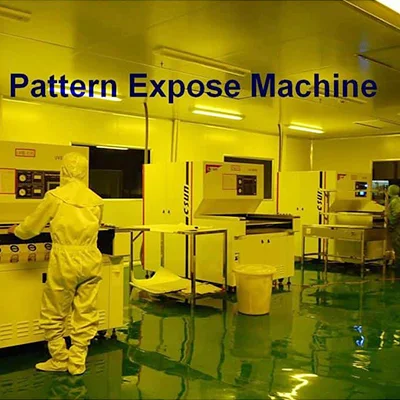

- PCB manufacturing equipment

Flexible Circuit Boards, or Flex PCBs, are a revolutionary advancement in printed circuit boards. Unlike rigid PCBs, Flex PCBs offer exceptional flexibility, allowing them to bend, twist, and conform to the shape of the device or system they are integrated into.

This flexibility opens up a new realm of possibilities for electronic designs, especially in applications involving space constraints, complex geometries, or dynamic movements.

Flex PCBs find applications in various industries, including consumer electronics, medical devices, automotive systems, wearable technology, aerospace, and more. Their ability to conform to complex shapes and withstand dynamic movements makes them suitable for applications that require flexibility, durability, and reliability.

The fabrication capabilities for flexible printed circuit boards (FPCs) can vary among manufacturers. However, here are some common capabilities associated with FPC fabrication:

- Layer count: FPCs can be manufactured with single-sided, double-sided, or multilayer configurations, depending on the complexity of the circuit design and the requirements of the application. Multilayer FPCs can provide increased functionality and density.

- Substrate materials: FPCs are typically made using flexible materials such as polyimide (PI) or polyester (PET). The choice of substrate material depends on the desired mechanical properties, thermal resistance, and specific application requirements.

- Copper weight and thickness: FPCs can be fabricated with different copper weights and thicknesses to accommodate various current-carrying capacities and design considerations. Common copper thicknesses for FPCs include 0.5 oz, 1 oz, and 2 oz.

- Circuit trace width and spacing: FPC manufacturers can produce circuit traces with precise widths and spacing to meet specific design requirements. The capabilities for trace width and spacing depend on the manufacturing processes and equipment used by the manufacturer.

- Surface finishes: FPCs can be finished with different surface treatments to protect the copper traces and enhance solderability. Common surface finishes include Electroless Nickel Immersion Gold (ENIG), Immersion Silver, HASL (Hot Air Solder Leveling), and OSP (Organic Solderability Preservatives).

- Solder mask and legend printing: FPCs can have solder mask coatings applied to protect the copper traces and prevent solder bridges during assembly. Legend printing is the process of adding component designators and other identifying marks to the board for assembly and troubleshooting purposes.

- Panelization and routing: FPC manufacturers can panelize multiple FPCs on a single panel for efficient production. They can also provide routing services to separate the individual FPCs from the panel while ensuring clean and accurate cuts.

- Quality control and testing: Reputable FPC manufacturers have robust quality control processes in place to ensure that each board meets the specified requirements. They may conduct various tests, such as electrical continuity testing, impedance testing, and dimensional checks, to verify the integrity and performance of the FPCs.

Advantages of Flexible Circuit Boards :

- Space Efficiency: Flex PCBs excel in space-constrained applications where traditional rigid PCBs may not fit or be too bulky. This also makes Flex PCBs ideal for compact electronic devices or systems with irregular shapes.

- Weight Reduction: Flex PCBs are lightweight compared to rigid PCBs, contributing to overall weight reduction in electronic devices. This advantage is especially crucial in aerospace, automotive, and also in portable electronics industries, where weight savings are essential for improved performance and portability.

- High Reliability: Flex PCBs are designed to withstand repetitive bending and flexing without compromising functionality. They are made with specialized materials that offer excellent flexibility, resilience, and durability.

- Enhanced Design Flexibility: Flex PCBs offer unparalleled design flexibility, allowing intricate and three-dimensional circuit layouts. They can be shaped to match the product’s contours, enabling efficient use of available space.

- Increased Signal Integrity: Flex PCBs offer excellent electrical performance and signal integrity. They can be designed with controlled impedance, minimizing signal loss, crosstalk, and electromagnetic interference (EMI). The absence of connectors and cables also reduces the risk of signal degradation.

PCB Drilling machine

PCB pattern plating line

PCB solder mask expose machine

PCB pattern expose machine

Strip film etching line

Solder mask screen silk print machine

Solder mask scrubbing line

PCB Flying Probe Test (FPT)

Fully automatic exposure machine