Origin; Origin: China

Certification: UL, CE, RoHS

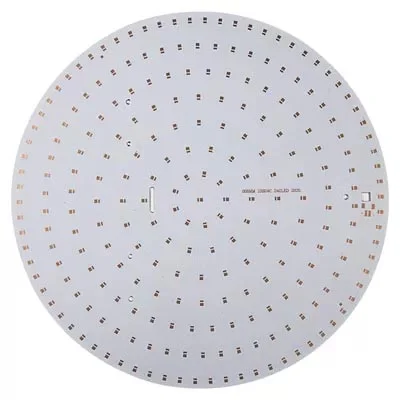

Model: growth light pcb05

Base material: aluminum

Board thick: 1.0/1.2/1.6mm

Copper thick: 0.5-3oz

print circuit board certificate: ISO9001: 2008, RoHS, UL

Component type: patch ThT DIP

Surface treatment: HASL Leadless

Application: LED growth light bar

Basic Information

Origin; Origin: China

Certification: CE, ROHS, UL

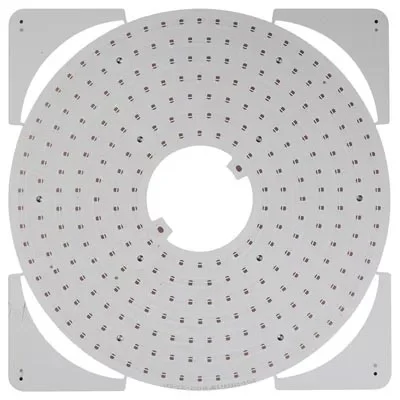

Model: Aluminum Base Plate 01

Base material: aluminum base

Copper thick: 1/2 ounce

Dipping: 0.3-0.5mm

Imitation: Wiring, V-CUT, Cutting

Service: One -stop service

Material: aluminum single -earthplate

Surface: operating system

Basic Information

Origin; Origin: China

Certification: CE, ROHS, UL

Model: Aluminum PCB circuit board 01

Base material :: aluminum base

Copper thick: 0.5 ounces, 1.0 ounces, 2 ounces, 3 ounces

Board thick: 0.2mm -4mm

minute. The size of the hole: 0.25mm (10mils)

minute. Width: 0.25mm (10mils)

V-CUT angle: 20, 25, 30, 45 degrees

Basic Information

Origin; Origin: China

Certification: CE, ROHS, UL

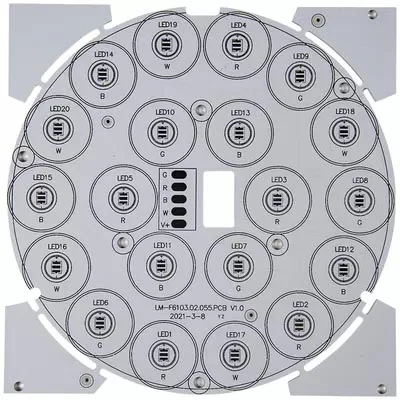

Model: 12W LED PCB board

minute. The size of the hole: 0.25mm

Silk print: white, black, yellow

Electrical test: fixture/flying needle

Kong tolerance: PTH: ± 0.075, NTPH: ± 0.05

Service: One -stop service

Basic Information

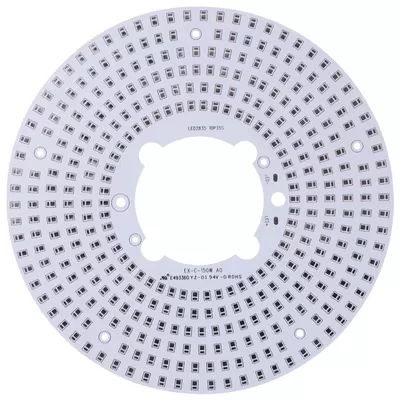

Origin; Origin: China

Certification: UL, CE, RoHS

Model: Electronic LED PCB 01

Base material: electronic product LED PCB

LED chip: 2830 5730 3535 5050 3030

Backbility: 94V0

Board size: customized

Surface treatment: HASL Leadless

Application: Light

Basic Information

Origin; Origin: China

Certification: CE, ROHS, UL

Model: Aluminum Base Plate 01

Base material: aluminum base

Copper thick: 1/2 ounce

Board thick: 1.2mm

Size: Customized

Service: One -stop service

- Aluminum PCB Capability

- PCB manufacturing equipment

| Aluminum PCB Capability | ||

| Aluminum PCB Feature | Parameter (in) | Parameter (mm) |

| Layers | 1 – 6 | 1 – 6 |

| Max Board Size | 24” x 40” | 609.6 x 1016mm |

| Min Board Thickness – 1-2 (layers) | 16mil | 0.4mm |

| Min Board Thickness – 4 (layers) | 20mil | 0.5mm |

| Min Board Thickness – 6 (layers) | 24mil | 0.6mm |

| Board Thickness Range | 16 – 157mil | 0.4 – 4mm |

| Max Copper Thickness | 5oz | 175um |

| Min Line Width / Space | 4mil / 4mil | 0.1 / 0.1mm |

| Min Hole Size | 20mil | 0.5mm |

| PTH Dia. Tolerance | ±2mil | ±0.05mm |

| NPTH Dia. Tolerance | ±1mil | ±0.025mm |

| Hole Position Deviation | ±4mil | ±0.1mm |

| Outline Tolerance | ±4mil | ±0.1mm |

| S/M Pitch | 3mil | 0.08mm |

| Aspect Ratio | 6:01 | 6:01 |

| Thermal Shock | 5 x 10Sec @288 | 5 x 10Sec @288 |

| Warp & Twist | <= 0.75% | <= 0.75% |

| Flammability | 94V-0 | 94V-0 |

Introducing our advanced Aluminum PCB, designed to meet the demanding needs of electronic applications. These specialized printed circuit boards offer exceptional thermal management and durability, making them the ideal choice for projects that require efficient heat dissipation.

With a lightweight yet robust aluminum substrate, our Aluminum PCB ensure reliable performance in various industries. Experience enhanced electrical performance, design flexibility, and cost-effectiveness with our PCBs, providing a reliable foundation for your electronic designs.

Our Aluminum PCBs find applications in industries such as automotive, aerospace, LED lighting, and power electronics. Their exceptional thermal management makes them suitable for various electronic devices and systems. Invest in our Aluminum PCBs to unlock the benefits of superior thermal management, durability, enhanced electrical performance, design flexibility, cost-effectiveness, and versatility

Aluminum PCBs, also known as metal-core PCBs or MCPCBs, have specific capabilities associated with their design and manufacturing processes. Here are some common capabilities related to aluminum PCBs:

- Base Material: Aluminum PCBs use aluminum as the core material. The aluminum core provides excellent thermal conductivity and heat dissipation properties, making them suitable for applications that require effective heat management.

- Layer Count: Aluminum PCBs can be manufactured with single-sided, double-sided, or multilayer configurations. The layer count depends on the complexity of the circuit design and the specific requirements of the application.

- Thermal Conductivity: Aluminum PCBs are known for their high thermal conductivity, allowing them to efficiently dissipate heat generated by electronic components. The thermal conductivity of the base material can vary, and higher values are desirable for better heat transfer.

- Dielectric Layer: Aluminum PCBs have a dielectric layer sandwiched between the aluminum core and the copper circuit layer. The dielectric layer provides electrical insulation and helps to distribute heat evenly across the board.

- Copper Thickness: Aluminum PCBs can be fabricated with different copper thicknesses to accommodate various current-carrying capacities and design considerations. The copper thickness is typically specified in ounces (e.g., 1 oz, 2 oz) and can be customized based on the application requirements.

- Surface Finishes: Aluminum PCBs can be finished with various surface treatments to protect the copper traces and enhance solderability. Common surface finishes include Electroless Nickel Immersion Gold (ENIG), HASL (Hot Air Solder Leveling), OSP (Organic Solderability Preservatives), and Immersion Tin or Silver.

- Solder Mask and Legend Printing: Aluminum PCBs can have solder mask coatings applied to protect the copper traces and prevent solder bridges during assembly. Legend printing, which adds component designators and other identifying marks, can also be applied to the board.

- Quality Control and Testing: Reputable aluminum PCB manufacturers have quality control processes in place to ensure that each board meets the specified requirements. Various tests, such as electrical continuity testing, thermal testing, and dimensional checks, may be performed to verify the integrity and performance of the aluminum PCBs.

Advantages of Aluminum PCB:

- Superior Thermal Management: Our Aluminum PCBs excel in dissipating heat, thanks to their highly conductive aluminum substrate. They efficiently transfer heat away from components, preventing overheating and ensuring optimal operating temperatures.

- Durability and Reliability: The aluminum substrate provides strength and resistance to mechanical stress, making our Aluminum PCBs durable and reliable even in challenging environments. They are less prone to damage from impacts, vibrations, and environmental factors.

- Enhanced Electrical Performance: With low thermal resistance and high thermal conductivity, our Aluminum PCBs offer improved electrical performance. They minimize power losses and voltage fluctuations, resulting in better signal integrity and overall system efficiency.

- Design Flexibility: Our Aluminum PCBs can be customized to suit your specific requirements. Choose from various sizes, shapes, and layer configurations to meet the unique needs of your project. Single-sided or double-sided options are available.

- Cost-Effective Solution: Compared to alternative materials, our Aluminum PCBs provide an excellent balance of performance and cost-effectiveness. They offer efficient heat dissipation at a more affordable price point, ensuring value for your investment.

PCB Drilling machine

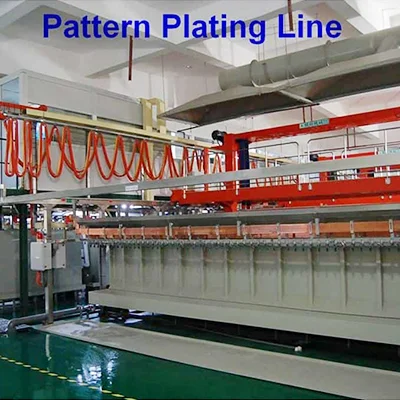

PCB pattern plating line

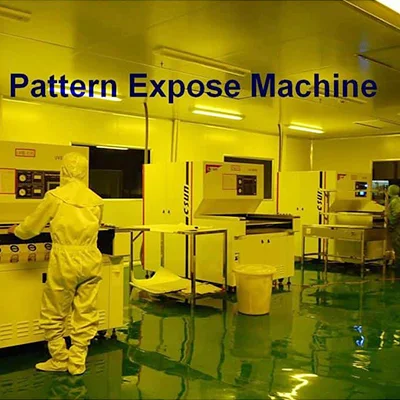

PCB solder mask expose machine

PCB pattern expose machine

Strip film etching line

Solder mask screen silk print machine

Solder mask scrubbing line

PCB Flying Probe Test (FPT)

Fully automatic exposure machine