OEM China electronic manufacturer assembly

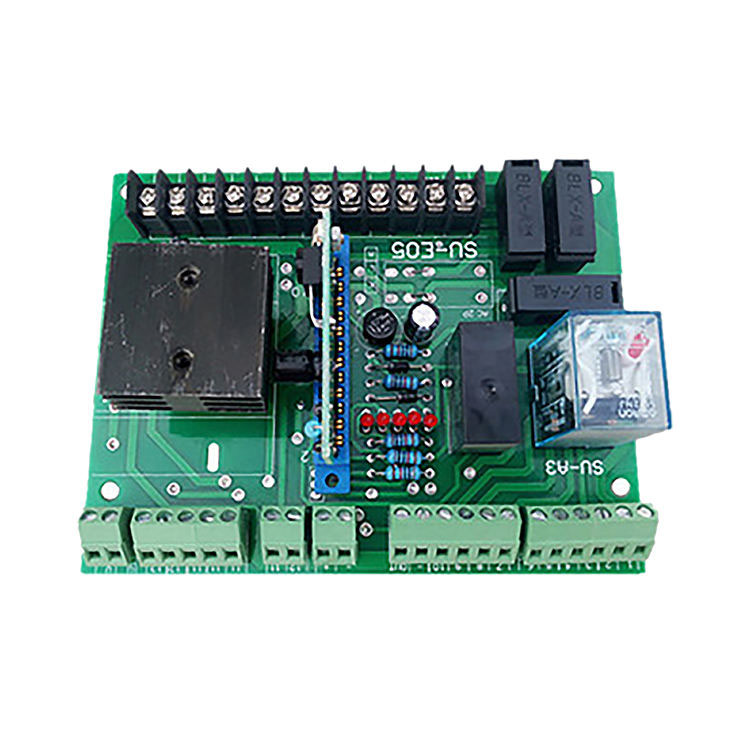

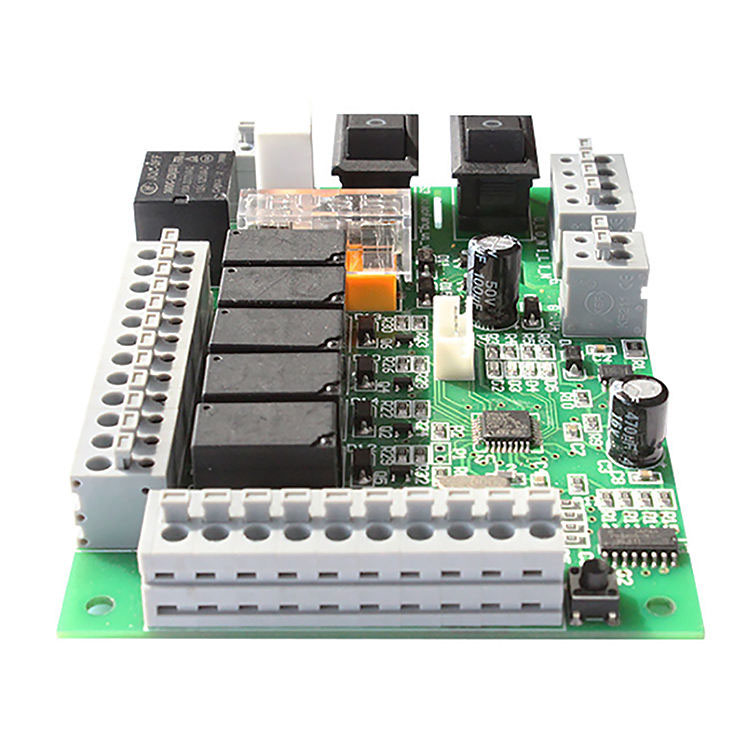

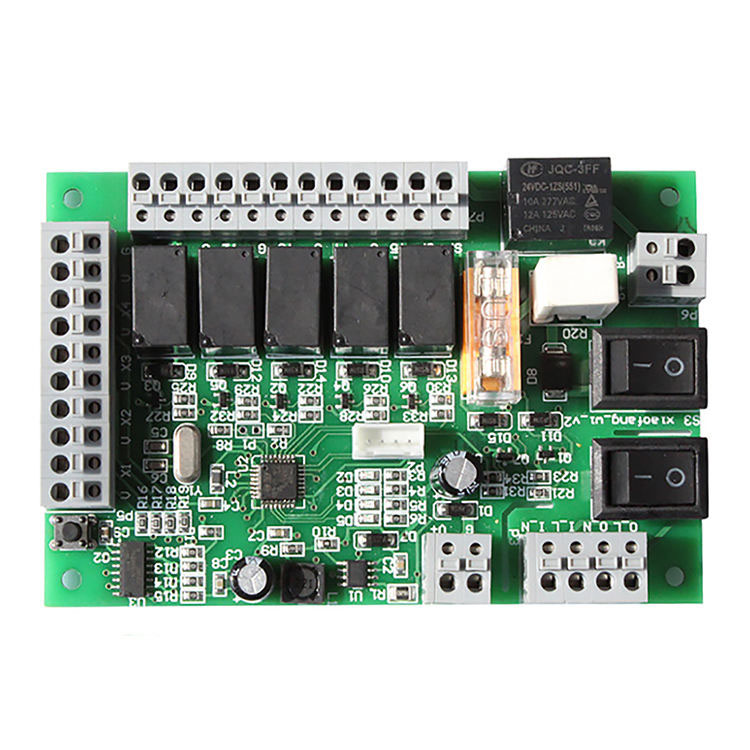

Type::home appliance pcba

Min solder mask bridge:>0.08mm

Finished board thickness:0.2-7.0mm

Min. Line Spacing:0.08mm

Min. Component Assembly:0.3mm IC,BGA,QFP,0201 components

Min.Hole Size:0.08mm

Min.Line Width:0.08mm

Accuracy of printing:±0.025mm

Copper Thickness:1-4oz

PCBA Service:SMT/DIP service

Repeated accuracy:±0.01mm

FOV size:61×45mm

Test speed:9150mm²/Sec

Shootingangle:0-45

When it comes to OEM (Original Equipment Manufacturer) electronic manufacturing and assembly, China is a prominent global hub. Many companies choose to partner with Chinese manufacturers for their expertise, cost-effectiveness, and efficient production capabilities. Here’s an overview of the OEM electronic manufacturing and assembly process in China:

- Manufacturer Selection: The first step is to identify and select a suitable OEM electronic manufacturer in China. There are numerous manufacturers with different capabilities and specialties, so thorough research, evaluation, and due diligence are essential. Factors to consider include their experience, reputation, production capacity, quality control processes, certifications, and cost competitiveness.

- Design and Engineering Support: Once a manufacturer is chosen, they typically provide design and engineering support. This involves collaborating with the OEM’s engineers to refine the product design, optimize the manufacturing process, and ensure the design is compatible with efficient assembly techniques like SMT.

- Component Sourcing: The OEM manufacturer assists in component sourcing, leveraging their supply chain networks and relationships with vendors. They can help procure quality electronic components at competitive prices, which is crucial for cost-effective production.

- Prototyping: Before proceeding with mass production, a prototype is usually developed. The manufacturer works closely with the OEM to manufacture a small batch of prototypes that can be tested and evaluated for functionality and quality. This stage allows for any necessary design revisions or improvements to be made before large-scale production.

- Manufacturing and Assembly: Once the prototype is approved, mass production begins. The OEM manufacturer handles the entire production process, including PCB assembly, component placement using SMT equipment, soldering, inspection, and testing. They have specialized production lines and equipment to efficiently assemble the electronic devices.

- Quality Control: Chinese OEM manufacturers place significant emphasis on quality control. They implement various quality control measures throughout the production process, such as automated optical inspection (AOI), X-ray inspection, functional testing, and burn-in testing. These measures ensure that the assembled electronic devices meet the specified quality standards.

- Packaging and Customization: After assembly and testing, the products are packaged according to the OEM’s requirements. Chinese manufacturers can provide various packaging options, including customized branding and labeling. They can also assist with product customization, such as adding firmware, software, or specific features requested by the OEM.

- Logistics and Shipping: Once the products are ready, the OEM manufacturer manages logistics and shipping. They coordinate the transportation, export documentation, and customs clearance processes to ensure the products reach their destination efficiently and on time.

- After-Sales Support: Chinese OEM manufacturers often provide after-sales support, including warranty services, repair, and maintenance. This ensures ongoing customer satisfaction and support for the products.

It’s important for OEMs to establish a clear and comprehensive partnership agreement with the Chinese manufacturer, defining the terms, expectations, intellectual property rights, confidentiality, and any other relevant aspects to protect the interests of both parties. Regular communication and collaboration throughout the manufacturing process are essential for a successful partnership.

Type::home appliance pcba

Min solder mask bridge:>0.08mm

Finished board thickness:0.2-7.0mm

Min. Line Spacing:0.08mm

Min. Component Assembly:0.3mm IC,BGA,QFP,0201 components

Min.Hole Size:0.08mm

Min.Line Width:0.08mm

Accuracy of printing:±0.025mm

Copper Thickness:1-4oz

PCBA Service:SMT/DIP service

Repeated accuracy:±0.01mm

FOV size:61×45mm

Test speed:9150mm²/Sec

Shootingangle:0-45