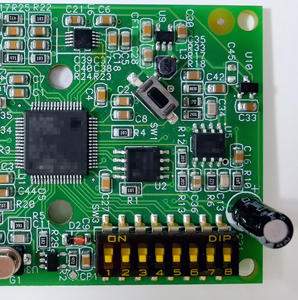

Monitor PCB Assembly Medical Device -Leadsintec

Name: Monitor PCB Assembly Medical Device -Leadsintec

Origin: China

Certified: UL, CE, RoSH

Board Thickness: 0.2mm-7.0mm

Surface Finishing: HASL\OSP\immersion Gold

Copper Thickness: custom

Solder mask color: Blue. green. red.

Application: Electronics Device

What does Monitoring PCB Assembly Medical Devices mean?

- The process of constructing the printed circuit boards (PCBs) used in medical monitors is called monitor PCB assembly for medical devices. Medical monitors are essential tools used in hospitals and other healthcare facilities to track patients’ physiological indicators, such as heart rate and electrocardiogram (ECG) measurements.

- A specialized electronic manufacturing business called “Medical PCB Assembly” assembles printed circuit boards (PCBs) for medical purposes. It entails the accurate and trustworthy assembly of PCBs in line with medical norms and standards as well as the strict needs of the medical business.

- The manufacture of electronic devices and equipment for various medical applications, including diagnostic tools, patient monitoring systems, imaging equipment, therapeutic devices, and more, depends heavily on medical PCB. These assemblies are built to resist demanding working conditions, guarantee patient security, and deliver dependable performance in demanding medical settings.

Why Is It Important to Monitor the Quality of Medical Devices PCB Assembly?

It’s critical to check PCB assembly quality in medical equipment for several reasons:

-

Patient Safety:

Medical equipment must be dependable and safe for patients, especially those in critical care or life-saving circumstances. Monitoring PCB assembly quality helps to reduce the possibility of faults or failures that might endanger patients and guarantees that the devices work as intended.

-

Compliance with laws:

Medical devices must adhere to strict laws and standards to guarantee their efficacy and safety. In the US, controlling agencies like the FDA have detailed rules for quality control in the production of medical devices. Monitoring PCB assembly quality helps to ensure adherence to these regulations, minimizing the risk of sanctions for non-compliance and subsequent recalls.

-

Performance and Reliability:

The PCB is the foundation of all electronic equipment, including medical devices. The PCB assembly quality directly impacts the medical equipment’s performance and dependability. By keeping an eye on the assembling procedure, producers may spot any problems that can jeopardize the device’s operation and fix them, avoiding failures or underperformance.

-

Monitor PCB Assembly Medical Device offer Cost and Efficiency :

Identifying and resolving quality issues during PCB assembly reduces the cost of manufacturing medical devices. Early mistake or defect identification reduces scrap, rework, and waste by preventing the manufacturing of defective equipment. Additionally, it reduces the need for expensive replacements or repairs made after the fact.

-

Reputation and Trust:

High-quality Monitor PCB Assembly Medical Device fosters trust among patients, healthcare professionals, and governing bodies. Monitoring PCB assembly quality displays a dedication to creating secure and dependable products, boosting the manufacturer’s reputation. Increased sales and relationships with healthcare organizations follow from a good reputation.

-

Product Consistency:

When producing medical equipment, consistency is essential. Monitoring PCB assembly quality ensures that each device operates consistently and satisfies the requirements across various units. Consistency is especially important for devices used in clinical studies since valid data requires constant performance and outcomes.