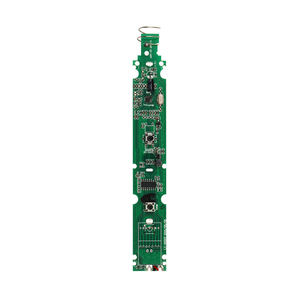

Mixed Signal Prototype PCB Assembly- low volume

Name: Mixed Signal Prototype PCB Assembly- low volume

Origin: China

Certified: UL, CE, RoHS

Base Material: FR4 CEM1 CEM3 Aluminum

Number of Layers: 4-layer, 1-32 layers

Copper Thickness: 1oz, 1OZ

Board thickness: customized

Why is Mixed Signal Prototype PCB Assembly Gaining in Popularity?

Combining analogue and digital components on a single board is possible thanks to mixed signal printed circuit boards (PCBs). For much contemporary electrical equipment that needs to process both analogue and digital data, this integration is crucial. Sensors, data collecting systems, audio devices, and communication devices are a few examples. Mixed Signal Prototype PCB Assembly offers a small and effective solution by mixing analogue and digital components on a single board.

- In the past, analogue and digital circuits were frequently created independently, needing a number of boards and connectors to join them. Because separate boards are not required with mixed signal PCB assembly, production, assembly, and material costs are reduced. Less connections and interconnects also result in increased dependability and less maintenance.

- Electronic equipment may be made smaller with the use of mixed signal PCBs. The total size of the device can be greatly decreased by combining analogue and digital circuitry on a single board. This is crucial for portable and handheld devices since they have limited space. Additionally, because to the tiny size, applications that were previously restricted to either analogue or digital can now incorporate mixed signal capabilities.

- Mixed signal PCBs make it easier to enhance the overall performance of the system. Signal integrity can be increased by tightly integrating analogue and digital circuitry, which lowers noise and interference between various components. In applications including data conversion, signal processing, and measurement systems, this integration provides more accurate control, filtering, and conditioning of signals, improving performance and accuracy.

Importance of Mixed Signal Prototype PCB Assembly:

When creating and testing electrical devices that incorporate analogue and digital circuits, mixed signal prototype PCB assembly is crucial.

-

Mitigating Noise and Interference:

PCBs for mixed signal systems typically encounter interference and noise problems. Noise may affect analogue transmissions, and it can even enter the analogue domain through digital signals. The detection and mitigation of noise and interference problems are made easier by prototype PCB construction. To decrease noise and guarantee correct signal processing, engineers can evaluate the performance of the mixed signal circuits and put in place the necessary steps, such as adequate grounding, shielding, and signal conditioning.

-

Testing and validation:

Mixed signal prototype for testing and validation the performance of the combined analogue and digital circuits may be tested and validated using a PCB assembly as a platform. Engineers may use it to analyze how various signal types interact and spot any possible problems or interference. Engineers may hone and optimize the design during the prototype assembly process to guarantee optimum functionality and performance.

Provides in speeding up the time:

Another factor contributing to the popularity of mixed signal prototype PCB assembly is the benefit it provides in speeding up the time it takes for new electrical devices to hit the market. The design and development cycle can be accelerated by using a single board with both analogue and digital functionality. It speeds up iterations and iterations, shortening the time needed for product development. It also makes testing, troubleshooting, and debugging procedures simpler.