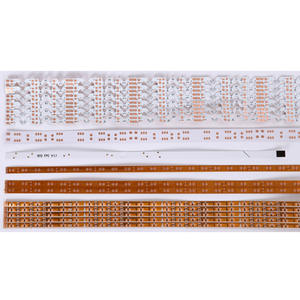

LED Lightening Double-sided PCB Assembly

Name: LED Lightening Double-sided PCB Assembly

Origin: China

Certified: UL, CE, RoHS

Surface Finishing: HASL LEAD FREE

Board Size: customized

Application: Christmas decorate lighting

Material: FR4 /aluminum/CEM1

Copper: 1-5 oz

Solder mask: White/Black/other customized

What exactly is LED Lightening Double-sided PCB Assembly for?

Double-sided PCB assembly for LED lighting is the process of putting together a printed circuit board (PCB) with components on both sides of the board. It is particularly made for LED lighting applications. After testing, the PCB assemblies undergo a final examination to ensure they satisfy the necessary quality requirements. This is followed by packing. The assemblies are normally packaged and ready for shipment after receiving approval, or they may be further incorporated into the LED lighting products. A broad description of the LED Lightening Double-sided PCB Assembly is given below:

-

Design:

When creating the PCB, consideration is given to the particular needs of the LED lighting application, including the quantity and positioning of LEDs, the power needed, and any extra components required.

-

Component placement:

The construction of LED PCBs frequently uses surface mount technology (SMT). Automated pick-and-place machines install LED components and other surface-mounted parts on both sides of the PCB, including resistors, capacitors, and integrated circuits.

-

Application of solder paste:

A solder and flux mixture is applied to the pads on the printed circuit board (PCB) where components will be installed. This paste assists in keeping the parts in place when soldering.

-

Reflow soldering:

The PCB is put through a reflow oven, where a controlled temperature melts the solder paste, connecting the components to the PCB pads. Typically, a conveyor system is used in this procedure to move the PCB through several temperature ranges, allowing the solder to reflow and provide strong electrical connections.

-

Inspection:

The assembled PCB is examined for any soldering flaws once soldered, such as alignment issues, solder bridges, or inadequate solder connections. To guarantee the quality of the assembly, automated optical inspection (AOI) equipment or human inspection methods may be utilized.

-

Secondary side assembly:

Additional components, such as connections, power management ICs, or heat sinks, may need to be installed on the secondary side of the PCB in LED lighting applications. Similar methods for the major side assembly are used to position and solder these components.

-

Testing:

After the assembly, functional testing is carried out to ensure the LED lighting PCB complies with the required standards. This might entail turning on the circuit board and ensuring that the LEDs operate properly, checking voltage levels and current use, or using specialized equipment to gauge the light output and color quality.

Benefits of installing LED Lightening Double-sided PCB Assembly:

-

Space efficiency:

Double-sided PCBs make Effective use of space possible, allowing for more compact designs. The total footprint of the PCB may be decreased by putting components on both sides of the board, making it appropriate for applications with restricted space.

The assembly can hold more components, such as LEDs, resistors, capacitors, and ICs when components are positioned on both sides of the PCB. This enables LED lighting solutions to be more versatile and practical.

-

Improved thermal management:

LED lighting assemblies produce heat; LED lifetime and performance depend on efficient thermal management. A double-sided PCB integrates more heat dissipation elements, such as copper pours or heat sinks, which improves heat dispersion and dissipation.

-

Superior electrical performance:

Double-sided PCBs can offer superior electrical performance by reducing signal interference and optimizing signal routing. Shorter and more direct signal routes are made possible by the ability to route traces and install components on both sides of the board, lowering signal loss and enhancing overall electrical integrity.

-

Cost-effectiveness:

Despite being slightly more difficult than single-sided assembly, LED Lightening Double-sided PCB Assembly can be less expensive than more sophisticated multilayer PCBs. Since they can be produced cheaply and are often utilized, double-sided PCBs are an economical option for LED lighting applications.

-

Flexibility in assembly:

Double-sided PCBs provide you with additional options when it comes to assembly. Both sides of the component may be used, making assembly quick and facilitating testing, inspection, and maintenance.