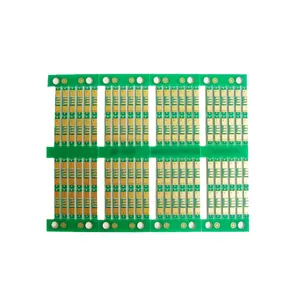

Heavy Copper Low PCB Assembly for Electronic

Name: Heavy Copper Low PCB Assembly for Electronic

Origin: China

Certified: UL, CE, RoHS

Copper Thickness: 1 oz

Solder Mask Color: Double-sided green LPI, Also support red, white, yellow, blue, black

Board thickness: customized

What is Heavy Copper Low Volume PCB assembly?

Manufacturing electrical devices may be done more affordably with the help of Heavy copper low PCB assembly. It enables for greater dependability for a number of applications and higher current handling capacities, heat dissipation, and efficiency. Additionally, speedy and effective completion of heavy copper low volume PCB assembly offers a workable response to many requirements for the manufacture of electronic devices.

Heavy copper low volume PCB assembly is an excellent choice

-

Enhanced current carrying capacity:

Heavy copper PCBs are able to handle larger current levels. It is perfect for systems that deal with high current densities or high power requirements, such as power electronics, automobile systems, industrial machinery, or renewable energy systems.

-

Good thermal control:

It improved thermal conductivity is a result of their larger copper thickness. They are ideally suited for applications that create a lot of heat because of the improved heat dissipation and dispersion that results from this. To avoid overheating and to guarantee the dependability and lifetime of electronic components, effective thermal management is essential.

-

Enhanced mechanical strength:

Heavy copper PCBs have more copper mass, which contributes to their robustness and endurance. These boards are appropriate for harsh settings or applications that need greater strength and resilience since they can endure higher degrees of stress, vibration, and mechanical impact.

-

High power density design

High power density designs are made possible by heavy copper PCBs because they have a greater copper cross-sectional area. As a result, designers can fit more functionality and power into a smaller space. Compact gadgets or systems with little accessible space benefit most from it.

-

Low-volume manufacturing:

For low-volume production runs, heavy copper assembly is a wise financial decision. Traditional techniques are used, which are better suited for smaller numbers, such etching and plating.

Application of Heavy Copper Low Volume PCB Assembly

-

Industrial machinery:

Heavy Copper Low PCB Assembly is ideal for industrial machinery that must work in harsh conditions. This comprises high-powered machinery, control panels, industrial automation systems, and motor controllers. The improved heat dissipation and durability provided by the thicker copper allow for dependable operation under demanding industrial circumstances.

-

Medical devices:

Where high power density, thermal control, and longevity are crucial, heavy copper PCB is used. Surgical tools, patient monitoring systems, diagnostic tools, and medical imaging equipment are a few examples. In medical settings, the sturdy copper design ensures dependable power distribution and aids in maintaining constant performance.

-

Power electronics:

Applications requiring strong current handling capabilities in power electronics frequently employ heavy copper PCBs. This comprises battery management systems, motor drives, inverters, power supply, and systems for charging electric vehicles. The increased copper thickness lowers the possibility of heat problems while enabling effective power delivery.