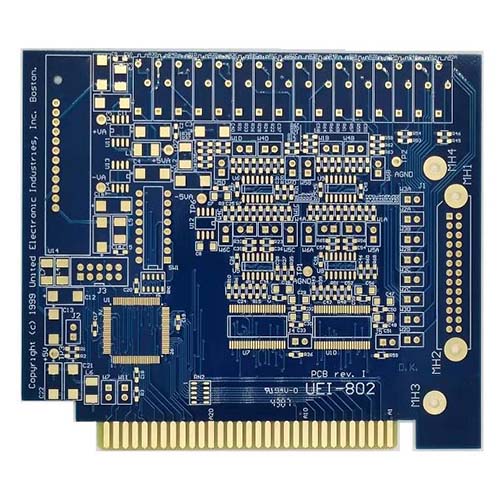

Double-sided gold finger circuit board

Name: Double-sided gold finger circuit board

Plate: FR4

Layers: 2L

Material: S1141

Plate thickness: 1.6mm

Copper thickness of inner and outer layers: 1oz

Minimum aperture: 0.3mm

Surface Treatment: Immersion Gold

Line width: 0.15mm

Line distance: 0.15mm

Others: electroplating gold fingers

Blind hole structure: L1-L2

Use: board, interface

Double-sided gold finger circuit board Gold-finger PCBs are those with gold-finished finger-like pads that are typically used as edge connectors.

Electroless gold has excellent solderability, but the chemical deposition process means it is too soft and thin to withstand repeated wear and tear. Gold plating is thicker and harder, making it ideal for re-mating PCB edge connector contacts.

Gold finger PCBs also often have to be chamfered at the edge connectors to ensure easy insertion. Bevel cuts can be specified in the order details if specifically stated.

Gold fingers are the gold-plated posts you see on the edge of a printed circuit board (PCB) connection. The purpose of the golden finger is to connect the auxiliary PCB to the motherboard of the computer. PCB gold fingers are also used in various other devices that communicate via digital signals, such as consumer smartphones. Gold is used for connection points along the PCB due to the alloy’s excellent electrical conductivity.

Kinds of gold suitable for PCB gold finger plating process

There are two kinds of gold suitable for PCB gold finger plating process:

Electroless Nickel Immersion Gold (ENIG): This gold is more cost-effective and easier to solder than electroplated gold, but its soft, thin (typically 2-5u” composition makes ENIG unsuitable for circuit board insertion and removal wear and tear Effect.

Electroplated hard gold: This gold is solid (hard) and thick (usually 30u”), so it is more suitable for the abrasive effects of continuous use of the PCB.

Gold fingers enable different circuit boards to communicate with each other. From a power source to a device or equipment, a signal must pass between multiple contacts in order to execute a given command.

The gold fingers should not have any contact with the solder mask or silk screen, and the two should be kept at a certain distance.

Double-sided gold finger circuit board must always face opposite the middle of the PCB (if you want the edge beveled)

Gold is used for the connection fingers on the PCB because of the alloy’s excellent strength and electrical conductivity. The strength of the gold allows fingers to be inserted and ejected hundreds of times without fraying the connecting contacts. Without the protection of gold plating, the board can easily lose connectivity after a few uses.

As PCBs evolved into their modern form, gold was determined to be the most suitable connection contact metal due to a number of factors. The main advantages of gold are the electrical conductivity and also corrosion resistance of the alloy. For added strength, gold used in printed circuit boards is often combined with nickel or cobalt. For the electroplating process, the thickness of nickel is between 150 and 200 microinches.

Production standard for PCB

The production standard for PCB gold fingers was established in 2002 by the Connected Electronics Industry Association (IPC). These standards were revised in 2012 with the publication of IPC-4556. In 2015, these standards were revised again with the publication of IPC A-600 and IPC-6010. The IPC standards can be summarized as follows:

Chemical composition: For maximum rigidity at the edges of the PCB contacts, the gold plating layer should contain 5% to 10% cobalt.

Thickness: Gold finger plating thickness should always be in the range of 2 to 50 microinches. Standard thicknesses by size are 0.031″, 0.062″, 0.093″ and 0.125″. Lower thicknesses are typically used for prototypes, while higher thicknesses are used along connecting edges that are regularly inserted, unplugged, and reinserted.

Visual test: The visual test that the golden finger should be conducted through a magnifying glass. The edges should have a smooth, clean surface with no unwanted plating or the appearance of nickel.

Tape Test: To test the adhesion of gold plating to contacts, ICP recommends testing by placing a strip of tape along the edge of the contact. After removing the tape, inspect the tape for traces of plating. If there is significant gold plating on the tape, the plating lacks sufficient adhesion with the contacts.

Name: Double-sided gold finger circuit board

Plate: FR4

Layers: 2L

Material: S1141

Plate thickness: 1.6mm

Copper thickness of inner and outer layers: 1oz

Minimum aperture: 0.3mm

Surface Treatment: Immersion Gold

Line width: 0.15mm

Line distance: 0.15mm

Others: electroplating gold fingers

Blind hole structure: L1-L2

Use: board, interface