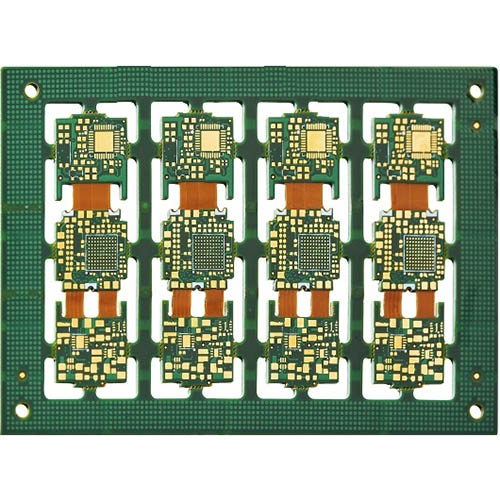

8-layer 2-stage HDI rigid-flex board

Name: 8-layer 2-stage HDI rigid-flex board

Layers: 8L

Structure: 3F+5R (8-layer 2-level HDI)

Sheet Type: PI, PET, PEN

Minimum hole: 0.1mm

PI thickness: 0.5mil-2mil

Cu Thickness: 1/3oz-2oz

Minimum line width/line spacing: 0.1/0.1mm;

NPTH Finished Aperture Tolerance: ±1mil(±0.025mm)

PTH Finished Aperture Tolerance: ±2mil(±0.050mm)

Finished plate thickness tolerance: ±0.01mm

Minimum line width/line gap: 0.05/0.05mm

Application field: High-end precision industrial sensor control board

Introducing the 8-layer 2-stage HDI (High-Density Interconnect) Rigid-Flex Board, an advanced solution designed for complex electronic applications that require high-density interconnections, flexibility, and compact form factors. This rigid-flex board combines the benefits of rigid and flexible substrates. It also offers superior functionality and design flexibility.

The 8-layer 2-stage HDI Rigid-Flex Board features eight layers of circuitry, providing ample space for intricate and densely packed designs. It employs advanced HDI technology, enabling high-density interconnections with smaller vias, finer traces, and tighter spacing between components. This results in improved signal integrity, reduced crosstalk, and also enhanced electrical performance.

The 2-stage design of the board offers even greater flexibility and design versatility. It allows for the incorporation of multiple rigid and flexible sections. This also enables optimal component placement and efficient signal routing. This facilitates efficient power distribution, noise reduction, and improved thermal management.

The HDI construction of the board ensures precise impedance control, impedance matching, and controlled signal propagation, minimizing signal reflections and ensuring accurate signal transmission. This makes it well-suited for applications that demand high-speed data transfer, such as telecommunications, high-speed computing, and aerospace.

The rigid-flex design combines the mechanical stability of the rigid sections with the flexibility of the flexible sections. This enables the board to conform to complex shapes, bend, twist, or fold, making it suitable for space-constrained environments and applications that require intricate geometries.

We see quality and credibility as the key to meeting the dynamic needs of our customers. Our rigid flex PCBs undergo rigorous testing, which helps us make the most accurate, timely and cost-effective designs. With the highest quality results and prompt service, our products meet the needs of many different markets, including the automotive, electronics, telecommunications, military, aerospace and defense industries.

Name: 8-layer 2-stage HDI rigid-flex board

Layers: 8L

Structure: 3F+5R (8-layer 2-level HDI)

Sheet Type: PI, PET, PEN

Minimum hole: 0.1mm

PI thickness: 0.5mil-2mil

Cu Thickness: 1/3oz-2oz

Minimum line width/line spacing: 0.1/0.1mm;

NPTH Finished Aperture Tolerance: ±1mil(±0.025mm)

PTH Finished Aperture Tolerance: ±2mil(±0.050mm)

Finished plate thickness tolerance: ±0.01mm

Minimum line width/line gap: 0.05/0.05mm

Application field: High-end precision industrial sensor control board